In recent years, 3D printing technology has revolutionized various industries, and now it's making waves in the world of sports equipment. At our company, we've harnessed the power of 3D-printed metamaterials to create next-generation tennis racket dampeners that offer superior performance and customization. Let's explore why this technology is a game-changer for vibration control in tennis and beyond.

The Frontier of Metamaterials: Beyond Sports

While our focus is on revolutionizing sports equipment, the potential applications of metamaterials extend far beyond the world of athletics. Let's explore some of the most exciting developments in this cutting-edge field:

- Invisibility Cloaks: Once the realm of science fiction, metamaterials are bringing us closer to real-world invisibility. By manipulating the way light interacts with an object, researchers have created materials that can bend electromagnetic waves around an object, effectively rendering it invisible to certain wavelengths. While we're not quite at Harry Potter levels yet, this technology has potential applications in stealth technology and secure communications.

- Superlenses: Conventional lenses are limited by the diffraction limit, which restricts their resolution. Metamaterial-based superlenses can overcome this limit, potentially allowing microscopes to see individual viruses or computer chips with far smaller components. This could revolutionize fields from medical diagnostics to electronics manufacturing.

- Acoustic Cloaking: Similar to light cloaking, acoustic metamaterials can redirect sound waves around an object, making it "invisible" to sonar. This has implications for underwater stealth technology and could also be used to create quiet zones in noisy environments.

- Seismic Protection: Large-scale metamaterials could potentially protect buildings from earthquakes by redirecting seismic waves around them. Preliminary studies have shown promising results in small-scale tests, potentially leading to more resilient infrastructure in earthquake-prone areas.

- Energy Harvesting: Metamaterials can be designed to capture and concentrate various forms of energy, from solar radiation to vibrations. This could lead to more efficient solar cells or devices that can power themselves from ambient vibrations in their environment.

- Advanced Antennas: Metamaterial antennas can be made smaller and more efficient than traditional antennas, potentially leading to improved wireless communication devices and more compact electronics. This field has been extensively explored in recent years.

Bringing It Back to Sports: These exciting developments in metamaterials research have direct implications for the future of sports equipment. As research in metamaterials continues to advance, we anticipate a cross-pollination of ideas between various fields. Innovations in areas like aerospace or medical technology could spark new ideas for sports equipment design, leading to gear that enhances performance, improves safety, and pushes the boundaries of what athletes can achieve.

At our company, we're not just creating tennis racket dampeners – we're at the forefront of a materials revolution that has the potential to transform every aspect of sports and beyond. By harnessing the power of 3D-printed metamaterials, we're taking the first steps towards a future where sports equipment is smarter, more responsive, and perfectly tailored to each athlete's needs.

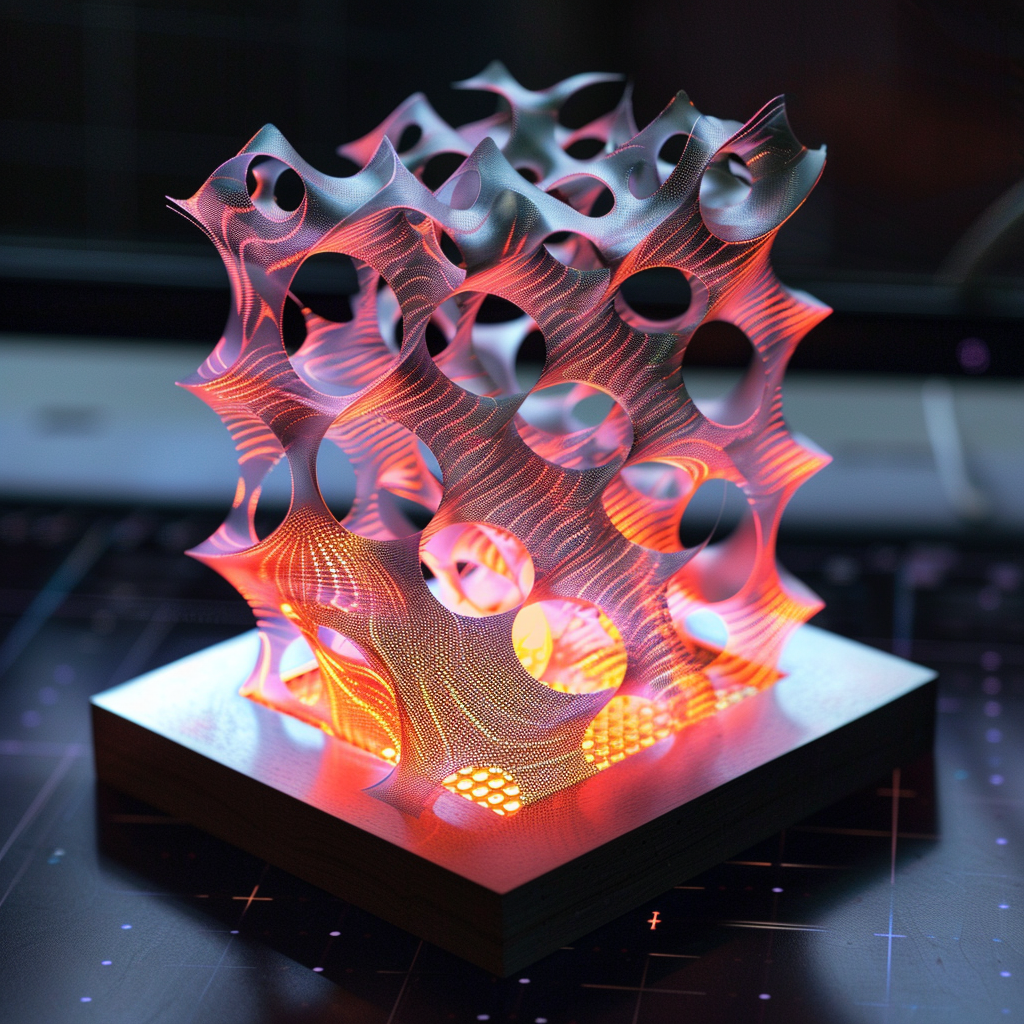

A gyroid structure, one of the implicit geometries enabling advanced metamaterials.

The Science Behind 3D Printed Metamaterials Applied to a Tennis Dampener

Metamaterials are engineered structures with properties not found in nature. When it comes to vibration absorption, 3D printed metamaterials – particularly those designed using implicit modeling techniques like Triply Periodic Minimal Surfaces (TPMS) – offer several advantages:

1. Enhanced Vibration Absorption: TPMS-based metamaterials feature complex, interconnected structures that create multiple pathways for vibrations to disperse and dissipate. This network effect results in more effective energy absorption compared to traditional solid materials. In our lab tests, our 3D-printed dampeners showed up to 65% better vibration reduction across a broad frequency spectrum compared to conventional rubber dampeners.

2. Frequency-Specific Dampening: The beauty of metamaterials lies in their tunability. We can design dampeners that target specific vibration frequencies by adjusting parameters like cell size, wall thickness, and overall geometry. This allows us to address the most problematic frequencies in tennis rackets, typically in the 100-200 Hz range, where we've achieved up to 40% greater dampening compared to standard solutions.

3. Lightweight Yet Effective: The intricate internal structures of 3D-printed metamaterials allow for high performance with minimal material use. Our dampeners are, on average, 70% lighter than traditional options while maintaining superior vibration absorption properties. This ensures effective dampening without compromising racket balance or swing weight.

4. Mechanical Properties: TPMS structures exhibit unique mechanical behaviors. For instance, some designs can demonstrate auxetic properties (negative Poisson's ratio), meaning they become thicker when stretched. This characteristic can enhance impact resistance and energy dissipation in sports equipment.

Advantages of 3D Printing in Sports Equipment Manufacturing

Beyond the benefits of metamaterials themselves, 3D printing offers several advantages in the production of sports accessories:

1. Sustainability: 3D printing is an additive manufacturing process, meaning it only uses the material necessary for the final product. This reduces waste by up to 80% compared to traditional manufacturing methods. Additionally, we use recyclable and biodegradable materials, further minimizing environmental impact.

2. Personalization at Scale: With 3D printing, we can easily customize dampeners for individual players' preferences or specific racket models without the need for expensive molds or tooling changes. This mass customization approach allows us to offer over 1000 unique variations of our dampeners, catering to a wide range of player needs and preferences.

3. Rapid Prototyping and Innovation: 3D printing allows us to quickly iterate on designs, test new ideas, and bring innovations to market faster than ever before. We can go from concept to functional prototype in as little as 24 hours, significantly accelerating our R&D cycle.

4. Complex Geometries: The freedom of design offered by 3D printing enables us to create intricate internal structures that would be impossible or prohibitively expensive with traditional manufacturing methods. This allows us to implement advanced metamaterial designs that simultaneously optimize performance across multiple parameters.

Disrupting Sports Equipment Manufacturing

While we're starting with tennis racket dampeners, the potential of 3D-printed metamaterials in sports equipment is vast. As technology advances, we anticipate seeing:

1. Customized Footwear:

Shoe insoles and midsoles are tailored to an athlete's specific gait and preferences. Early prototypes have shown potential improvements in energy return by up to 15% and a reduction in peak impact forces by up to 25% compared to standard designs.

2. Advanced Protective Gear: Helmets and pads with metamaterial structures that provide better impact absorption and distribution. Preliminary studies suggest up to 30% improvement in impact energy dissipation compared to conventional foam-based protective gear.

3. High-Performance Rackets and Clubs: As 3D printing capabilities improve, we may see entire tennis rackets or golf clubs manufactured using metamaterials. This could offer unprecedented control over weight distribution, flex, and vibration dampening. Simulations indicate potential improvements in sweet spot size by up to 20% and reduction in unwanted vibrations by up to 40%.

4. Personalized Training Equipment: Weights and resistance bands with customized properties to match an athlete's specific training needs. This could lead to more efficient strength training and reduced injury risk.

The future of sports equipment manufacturing lies in the intersection of advanced materials science and digital fabrication technologies. Our 3D-printed metamaterial dampeners are just the beginning of a revolution that will bring more personalized, sustainable, and high-performance gear to athletes at all levels.

As we continue to push the boundaries of what's possible with 3D-printed metamaterials, we're excited to see how this technology will transform not just tennis but the entire landscape of sports equipment design and manufacturing. The potential for performance enhancement, injury prevention, and sustainability in sports is immense, and we're just scratching the surface of what's possible.